Additional notes to Mines Safety Bulletin No 125 – Pneumatic Press SaFETY

Written by AME Operations Manager, Steve Ansell.

Manual Press Filter – an often forgotten classified plant item.

Following on from the Department of Mines and Petroluem’s Mines Safety Bulletin No 125, issued on 24 September 2015, it’s imperative to acknowledge that all pressure equipment has the potential to harm personnel or damage other equipment.

It’s worth noting that the Mines Safety and Inspection Regulations 1995 (MSIR 1995) state by definition that any pressure vessel is classified plant and therefore needs to be designed to AS 1210 to operate on a mine site.

Strictly speaking, if pressure equipment is operated on a mine site and is not designed to AS 1210, then a letter of exemption by the State Mining Engineer is required due to substantial compliance.

Following on from a number of recent inspections carried out by the Department of Mines & Petroleum (DMP) Inspectors, it has become apparent that various types of classified plant, namely pressure vessels – ‘a vessel subject to internal or external pressure’ – have been neglected with respect to the mine owners’ obligations with regards to inspections, maintenance and repairs.

Hazard Levels & Your Obligations

When referring to your obligations set out in MSIR 1995, one of the first things to do is to determine the Hazard Level of the pressure vessel to decide whether it falls under the category of “Pressure Equipment”.

To be classed as “Pressure Equipment”, as per the definition in the MSIR 1995, it must have a Hazard Level of A, B, C or D, according to the criteria set out in Part 1 of AS 3920 and therefore requires design verification. AS 3920 has been subsequently replaced by AS 4343:2014.

Hazard Level E vessels do not require design verification, which explains why it is almost impossible to source any relevant documentation such as design verification, Manufacturers Data Reports (MDR’s) etc. as they are optional.

When using AS 4343:2014 to determine the Hazard Level, both the design pressure and volume are required. The volume can easily be calculated, however, the design pressure can be more difficult to obtain, especially if the vessel is a Hazard Level E. From Clause 2.1.1 (d) of AS 4343:2014, Hazard Level E vessels are deemed to be of negligible hazard.

Air Receivers/Pneumatic Presses

For air receivers / pneumatic presses, for a starting point you should look at the source of compressed air and use the maximum working pressure of the source.

Generally air compressors are supplying compressed air at around 700kPa (100psi), however some compressors can have a maximum design working pressure upwards of 1.4MPa (203psi).

Always check the setting of the compressors Pressure Relief Valve (PRV) to validate these numbers and while doing this, ensure the test certificate is valid.

To determine the maximum volume of a pneumatic filter press, before it is considered as pressure equipment and becomes registerable classified plant, we can use the Hazard Level Formula in Clause 2.2.1 of AS 4343:2014, to calculate the volume.

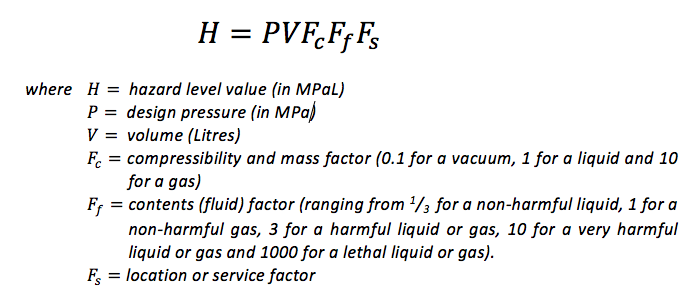

The hazard level value is calculated by the following formula:

In order for the pneumatic filter press to be considered as a Hazard Level E, and therefore not registerable, the hazard level value has to be less than or equal to 316MPaL (from Table 2.1, AS 4343:2014 ).

If we assume a design pressure of 1.4MPa, using compressed air which is a non-harmful gas

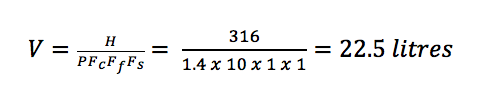

(Fc = 10, Ff = 1 and Fs = 1), the maximum volume before it becomes registrable classified plant is:

Therefore the maximum volume for a pneumatic filter press before it is considered pressure equipment and therefore registrable classified plant is 22.5 litres if the design pressure is 1.4MPa.

If the design pressure is less than 1.4MPa, then the maximum volume before it is considered pressure equipment will be greater and if the design pressure is greater than 1.4MPa then the maximum volume will be less.

Conclusion

In most cases the pneumatic filter presses are less than 22.5 litres and hence fall into Hazard Level E. Therefore, subject to the calculated result, the vessel will be deemed to be duty of care classified plant, so it won’t be required to have its design registered – however you should check with the supplier that it has been designed and built in accordance with AS 1210.

Remember, your classified plant register should contain all classified plant whether statutory or not. You are also responsible for providing your employees and contractors a safe place to work.

The team at AME are the industry leaders in Classified Plant inspections, audits, registration and procedures, helping you to ensure compliance and safety every step of the way.

This article was written by AME Operations Manager, Steve Ansell. For more information, please call (08) 9466 7444.

Related Articles: